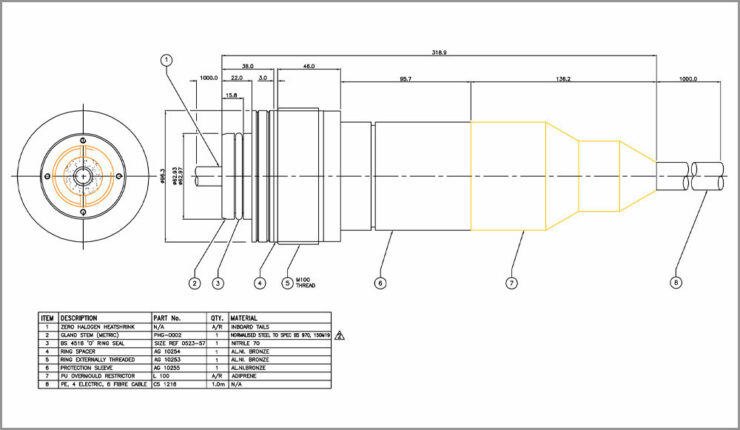

Designed specifically for submarines, pressure hull glands bring an electrical or optical circuit from the outside of a submarine's pressure hull to the inside. Various functional systems on a submarine are external to the hull, and pressure hull glands facilitate a safe route of power through the hull without interference.

Pressure hull glands penetrate the hull of a submarine, and endure high pressures during manoeuvres such as dives and rapid ascents, their integrity is vital to safeguard all functions and operation.

Our high integrity range of pressure hull glands has been tested extensively for performance and endurance, both internally and externally by third-party verification companies, and pressure and shock tested to PTS 14299. Importantly, our pressure hull glands have a proven track record over many years on local, national and international projects.

• Fully pressure blocked

• Proven Shock Tested Design / PTS 14299

• Metric and Imperial Thread Versions

• Electrical, Coaxial and Optical designs available

• Available in Normalised Steel / Nickel Aluminium Bronze (NAB) as standard

• Termination options include Polyethylene TSP, Coax Tails, composite Optical Electrical Tails

• Moulding options include Polyurethane and Polyethylene

Pressure Hull Glands

Pressure Hull Glands