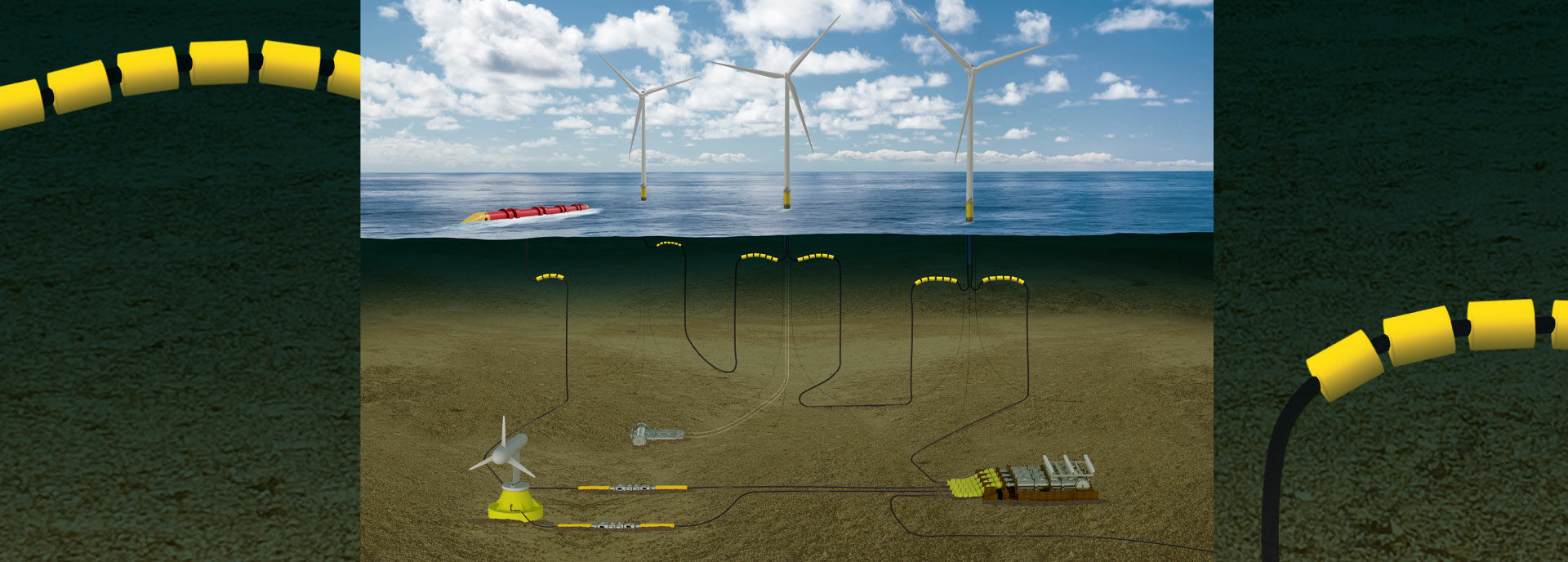

We’re at the forefront in the development of cables, terminations, connectors, and junction boxes, with involvement from the initial prototype stage through to design, manufacture, testing, certification, and installation. Our cable and connectivity solutions can withstand the harshest environmental conditions on earth, including saltwater, solar effects, storm-force winds, dynamic tidal, and wave motion.

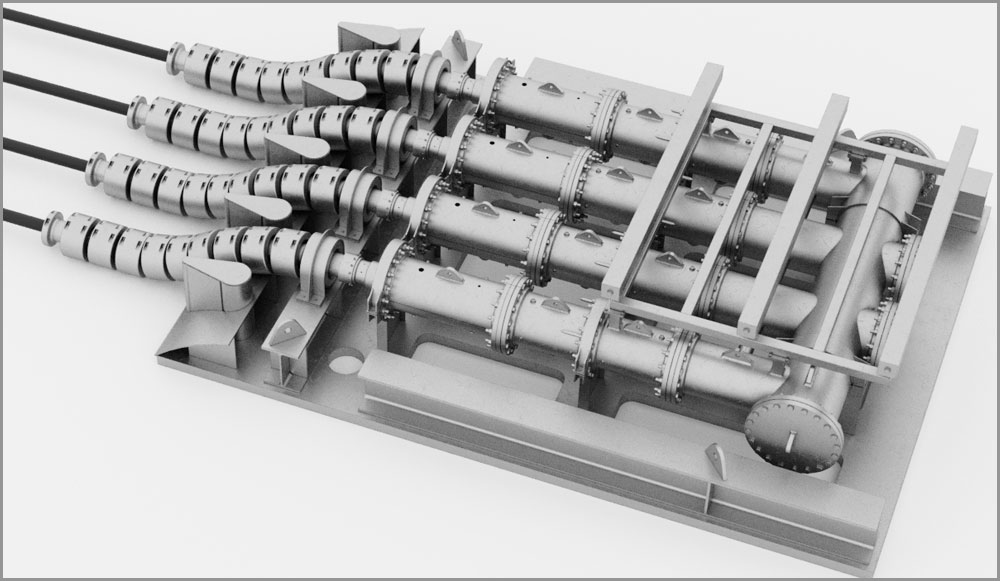

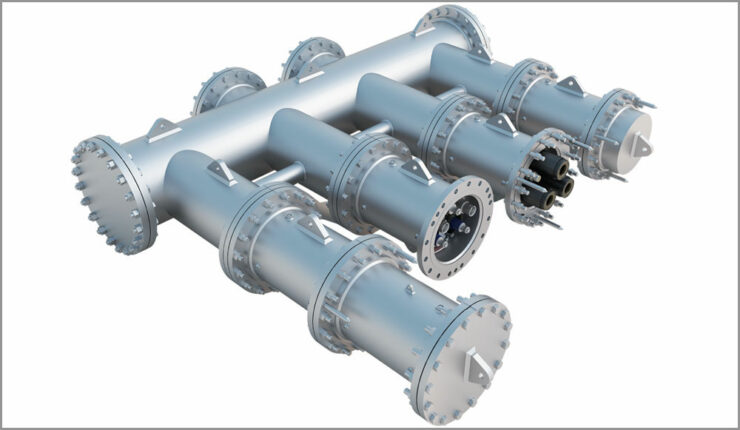

24kV Power Distribution Hub (PDH): Hydro Group’s Power Distribution Hub allows multiple energy devices to be connected to a single export cable, reducing the number of shore cables required and cutting the costs of the subsea cabling infrastructure for renewables projects. The hub utilises similar technology and 16" pipe flange interface as our HRC connector range. It means that HRC connectors or caps can be attached and removed quickly and securely, without the need for repeated re-terminations. The operating line voltages cover up to 24kV systems. Dual water ingress protection, as well as anti-corrosion properties, were incorporated into the design from the earliest stage, providing reliable sealing with a 20-year operational lifespan.

With certification approval to ISO 9001 : 2008, our electrical and optical connectors, associated subsea electrical cable terminations, specialist underwater and harsh environment electrical and optical composite cables, tethers, and umbilical cables are designed and manufactured in-house to exact requirements. Third-party verification on our testing procedures can also be delivered by surveying companies including Lloyd’s Register, Det Norske Veritas, and American Bureau of Shipping.

24kV PDH Power Distribution Hub

24kV PDH Power Distribution Hub

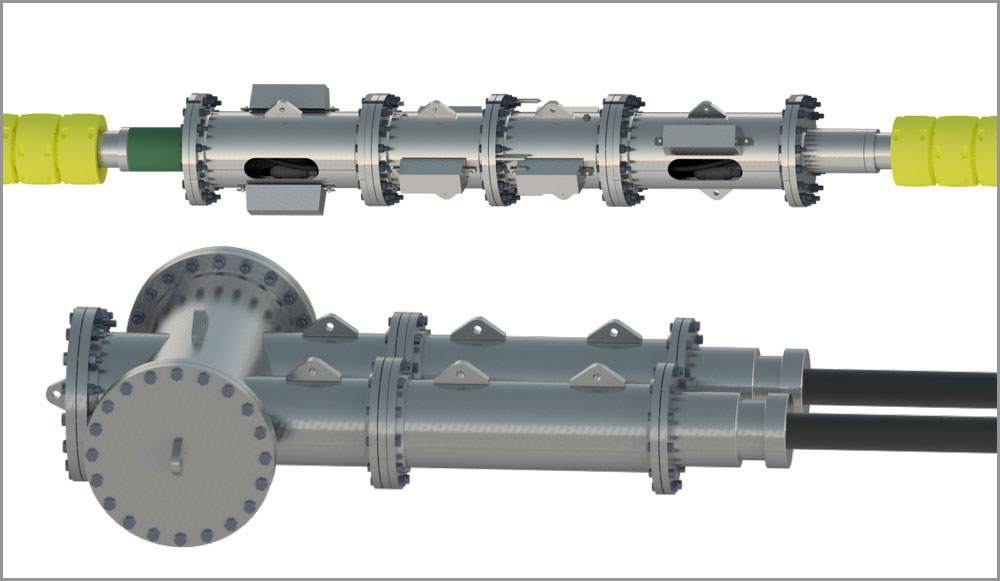

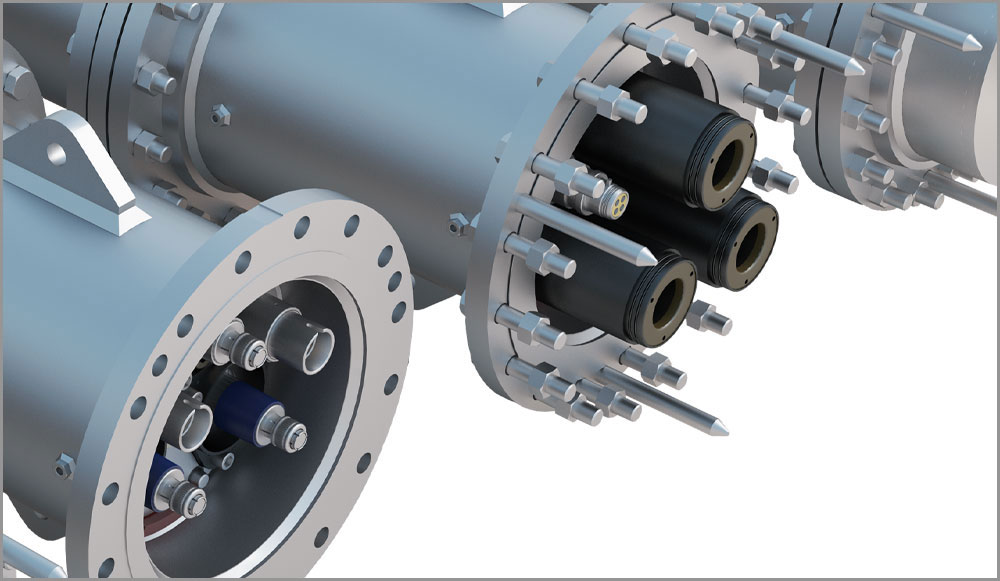

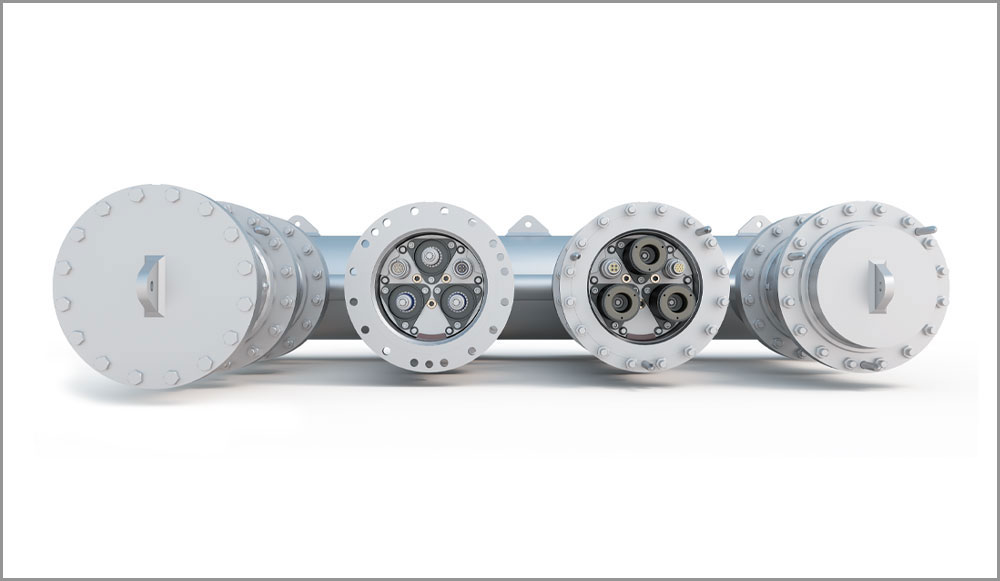

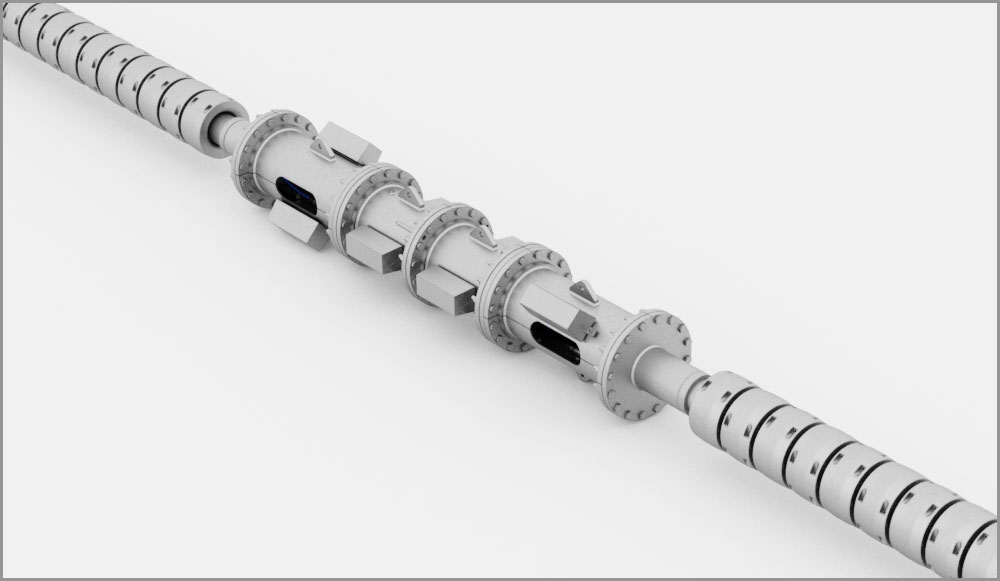

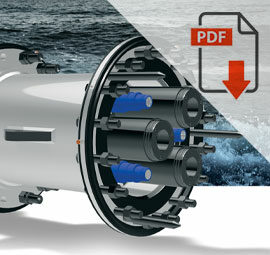

36kV HRC Hydro Renewable Connector

36kV HRC Hydro Renewable Connector